In the industrial sector, surface coating plays a crucial role in achieving product protection and performance optimization. Today, polyurethane spray technology is rapidly gaining prominence, bringing about new trends in coating for various industries. Let’s explore together why PU spray foam machines are becoming the leaders in the future of industrial coating.

PU spray technology has become the darling of the industrial sector due to its outstanding performance characteristics. Compared to traditional coating methods, polyurethane spray technology offers higher precision, more uniform coating, and superior weather resistance, making it stand out in multiple fields.

Our PU spray foam machines are built on high-precision spraying technology, ensuring uniform and reliable coverage on every inch of the surface. Whether it’s automotive exteriors, building structures, or industrial equipment, they showcase excellent coating results.

PU spray machines find widespread applications in electronics, automotive, construction, medical, and various other industries. Their multifunctionality makes them an ideal choice for a variety of industrial coating projects.

Our polyurethane spray machines are designed to be flexible, adapting to the requirements of different projects. Users can easily adjust coating speed, thickness, and patterns, achieving personalized customization to meet diverse coating needs.

Utilizing high-quality materials and a robust structure, our PU sprayers ensure long-term reliability. Their stability and durability provide a dependable coating guarantee for industrial production.

As industrial coating technology continues to evolve, polyurethane spray machines have emerged as the future choice, thanks to their advanced technology and outstanding performance. Choosing PU spray machines means opting for superior performance ahead of the curve and embracing future innovations on the coating journey.

PU spray foam machines play a crucial role in the automotive manufacturing process, widely used for car body painting, interior component coating, and application of corrosion-resistant coatings. Their efficient and precise spraying technology ensures consistency and durability on the vehicle’s surface, providing reliable quality for the entire vehicle.

PU sprayers play a crucial role in the maintenance and repair of industrial equipment. They can quickly apply protective coatings such as corrosion-resistant and wear-resistant layers, extending the lifespan of equipment.

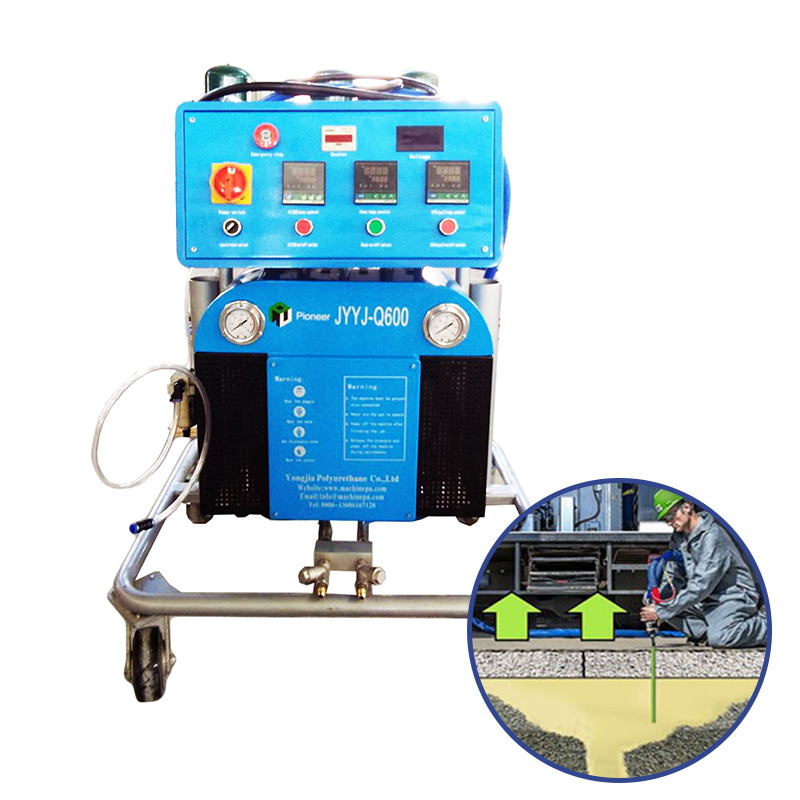

The application of polyurethane spray machines in slab lifting demonstrates outstanding performance. By utilizing polyurethane materials for spraying, it effectively achieves insulation and protection on the surface of slabs, providing a wear-resistant and corrosion-resistant barrier. Here is an overview of the main applications of polyurethane spray machines in slab lifting:

Copyright 2023 | All Rights Reserved | Powered by Alice Beauty