Investing in a polyurethane spray foam machine represents a significant business decision for contractors, with prices ranging dramatically from $1,500 for basic models to over $26,250 for professional-grade systems. The cost variation directly correlates with machine capabilities, including pressure systems, heating technology, and output capacity, making it crucial to understand these factors before making an investment that aligns with your specific project needs.

Key Takeaways

- PU spray foam machines range from $1,500 to $26,250+ depending on type and capabilities

- High-pressure systems cost more but offer superior performance and versatility for professional applications

- American-made equipment commands a price premium but typically provides better reliability and support

- Advanced features like digital controls and hydraulic systems justify higher investments through improved efficiency

- Hidden costs include maintenance, training, and facility modifications beyond the initial purchase price

The Cost Spectrum of PU Spray Foam Machines

PU spray foam machines come in a wide price range from $1,500 to $26,250+, reflecting the vast differences in quality, capabilities, and intended use cases. This significant price variance can be intimidating for newcomers to the industry who are trying to balance upfront costs against long-term business requirements.

The most important factors that influence pricing include the type of pressure system (high vs. low), heating capabilities, output capacity, and overall build quality. Entry-level machines typically feature basic components and limited output, while professional-grade equipment offers precision controls, higher durability, and greater production capacity.

For contractors just starting out, understanding these primary cost determinants helps in making an informed purchase decision. The pressure systems significantly impact price—high-pressure systems cost more but deliver better atomization and application control. Heating capabilities affect material viscosity and flow rate, with more sophisticated heating systems commanding higher prices but delivering more consistent results.

Output volume capability directly relates to efficiency and project turnaround time. Machines with higher output capacity allow contractors to complete jobs faster, justifying their premium price points through increased productivity and revenue potential.

Popular PU Spray Foam Machine Models and Their Prices

The market offers several established spray foam machine models across different price points. At the premium end, the Graco Reactor E-10 costs approximately $22,010 and features advanced temperature controls, reliable pressure management, and excellent material processing capabilities. This machine represents a significant investment but delivers professional-grade performance for serious contractors.

Moving up the line, the Graco Reactor E-20 reaches around $26,250 and provides enhanced output capacity, improved heating systems, and greater versatility for handling various material formulations. The additional investment delivers tangible benefits for high-volume contractors who need maximum efficiency and reliability.

In the mid-range market, the Master Pack Model 776 costs approximately $14,500 and includes heated hoses and auto-calibrating ratio pumps. This balance of advanced features at a more accessible price point makes it popular among growing contractors who need professional capabilities without the highest-end price tag.

Budget-friendly options under $5,000 typically include basic low-pressure systems with limited heating capabilities and manual controls. These entry-level machines can provide adequate performance for smaller jobs but may lack the consistency and output needed for commercial applications.

Mid-range machines ($5,000-$15,000) offer a solid compromise between price and capability, with improved heating systems, better pressure control, and more reliable components. Premium systems ($15,000+) add sophisticated digital monitoring systems, hydraulic drives, superior temperature management, and enhanced material handling capabilities.

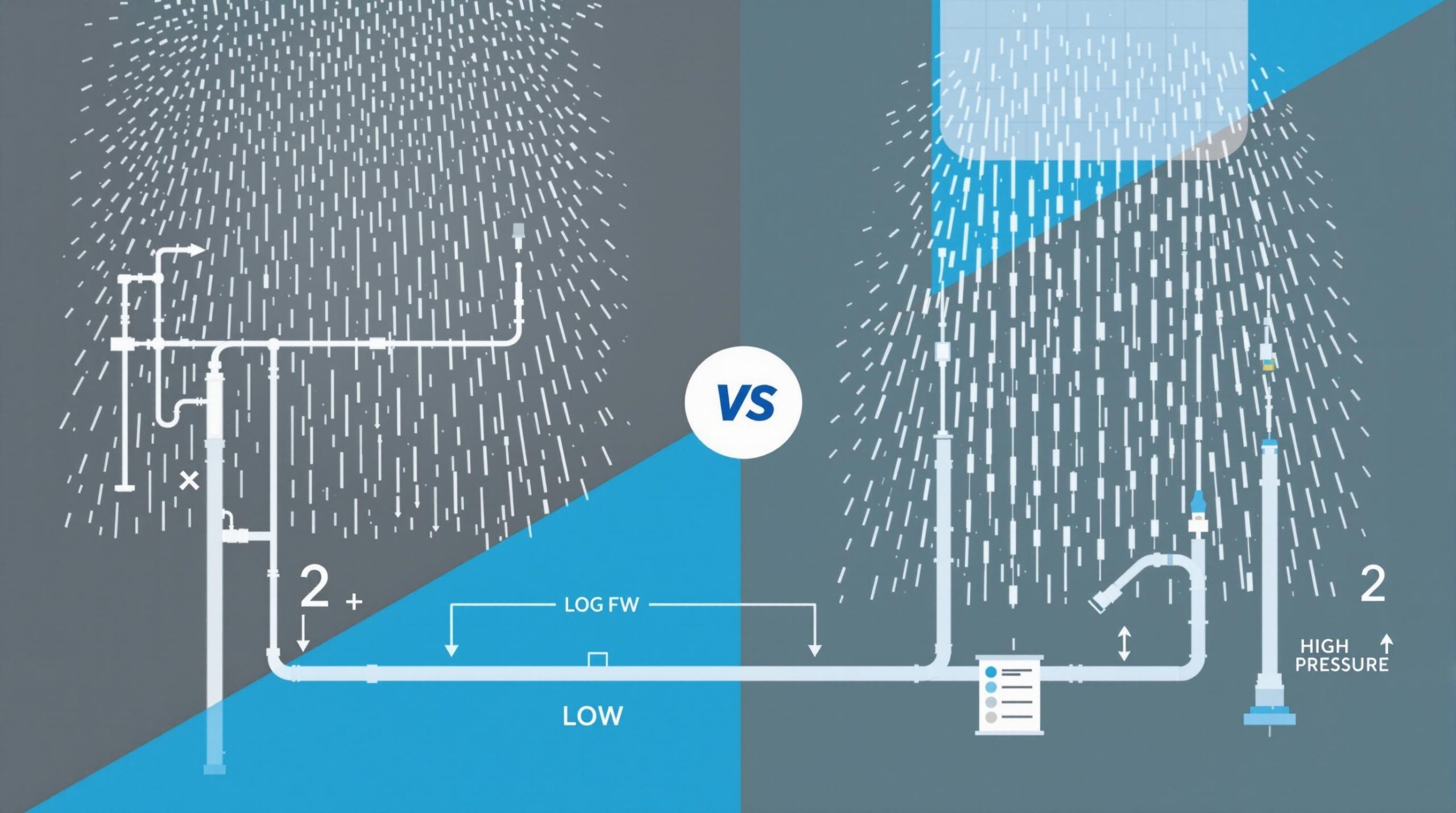

High-Pressure vs. Low-Pressure Systems

High-pressure spray foam systems typically cost between $10,000 and $26,250+ and represent the gold standard for professional applications. These systems generate pressures above 1000 psi, enabling excellent atomization, consistent cell structure, and superior bonding characteristics. The higher price reflects more powerful pumps, robust heating elements, and precision control systems.

The significant investment in high-pressure equipment is justified for commercial and industrial applications where performance and efficiency are paramount. These machines handle a wider range of material formulations and provide the consistency needed for critical insulation projects where R-value and air sealing must meet exact specifications.

Low-pressure systems, ranging from $1,500 to $8,000, operate below 600 psi and serve well for smaller residential projects, touch-ups, and specialty applications. The cost advantage comes from simpler pump designs, less robust heating requirements, and more basic control systems.

When deciding between these options, consider project scale and frequency. High-pressure systems become more economically viable for contractors completing multiple large projects, while low-pressure systems make sense for occasional use or supplementary capabilities. The performance difference justifies the price disparity for professionals who depend on their equipment daily, as high-pressure systems typically provide better yield, faster application rates, and more consistent results.

Advanced Features Worth the Investment

Data recording capabilities represent a valuable advanced feature worth considering in higher-end models. These systems track temperature, pressure, and material usage metrics, allowing for quality assurance documentation and helping optimize operations over time. Though adding $1,000-3,000 to the machine cost, this feature can prevent expensive rework by ensuring proper application parameters.

Hydraulic systems improve consistency through smoother pressure delivery and more reliable operation compared to pneumatic alternatives. The $2,000-4,000 premium for hydraulic drives pays dividends through reduced pulsation, more consistent material ratios, and lower maintenance requirements over the equipment lifespan.

Braided heated hoses enhance thermal efficiency and reduce material temperature fluctuations. This $500-1,500 upgrade improves foam quality by maintaining optimal material temperature from the machine to the spray gun, particularly valuable for projects in colder environments or with temperature-sensitive formulations.

Digital temperature and pressure controls offer precision that manual systems cannot match. The $1,000-2,000 additional cost provides finer adjustments, preset programming options, and better repeatability between jobs and operators. This precision translates directly to material savings and higher quality installations.

Multiple spray gun compatibility and quick-change components reduce downtime between material changes and maintenance operations. Though adding $800-2,000 to system cost, these features allow contractors to quickly switch between different application types or perform maintenance without extensive disassembly, increasing productive hours and job profitability.

American-Made vs. Imported Equipment

PMC Machinery exemplifies quality American-made equipment with simplified operation procedures and reliable performance standards. Their machines typically cost 20-40% more than imported alternatives but offer superior build quality, component standardization, and domestic support services that many contractors find essential.

By contrast, imported alternatives available through platforms like Alibaba may cost 30-50% less initially but often come with significant trade-offs. These savings must be weighed against potential issues with parts availability, technical support limitations, and inconsistent quality control.

The quality and reliability differences become apparent through warranty offerings. American manufacturers typically provide comprehensive 1-3 year warranties with clear support procedures, while imported equipment often comes with limited warranty protection and complicated claim processes that may require international shipping.

After-sales support represents a critical consideration that extends beyond the initial purchase price. American manufacturers maintain domestic technical teams, replacement parts inventories, and training resources that can minimize costly downtime when issues arise. This support infrastructure may justify the price premium for contractors whose business depends on equipment reliability.

The domestic manufacturing premium reflects higher labor costs, stricter quality control, and more comprehensive testing procedures. For full-time professional contractors, this premium often proves worthwhile through reduced downtime, longer equipment lifespan, and more consistent performance that clients notice and appreciate.

Return on Investment Calculations

The initial cost of a spray foam machine represents just one factor in a comprehensive return on investment analysis. A $25,000 professional-grade machine may seem expensive compared to a $5,000 entry-level system, but the productivity difference can be dramatic—often allowing completion of three to four times the square footage per day.

Higher-end machines typically improve productivity through faster application rates, reduced downtime, and more consistent performance that minimizes rework. A machine that applies foam 30% faster while reducing material waste by 15% can recover its premium cost surprisingly quickly for busy contractors.

To calculate potential revenue generation, consider that a professional-grade machine might enable application of 4,000-6,000 board feet daily versus 1,500-2,500 with an entry-level system. At typical contractor margins of $0.40-0.60 per board foot, this additional daily capacity can generate $1,000-2,000 in extra revenue per day.

Equipment lifespan considerations further support investment in quality. Premium machines typically offer 7-10 year operational lifespans with proper maintenance, compared to 2-4 years for budget models. The longer service life effectively reduces the annual cost of ownership despite the higher initial investment.

For contractors to justify different price points, consider the project volume needed. A basic calculation suggests that premium equipment requires approximately 40,000-60,000 board feet of additional installation to recover the incremental investment compared to budget options—a volume that busy contractors can achieve within months rather than years.

Spray Foam Insulation Cost Comparison

Material costs for spray foam insulation typically range from $0.45 to $1.50 per board foot, significantly higher than traditional insulation methods like fiberglass ($0.40-0.60/sq.ft.) or cellulose ($0.35-0.55/sq.ft.). However, the superior performance characteristics of spray foam justify this premium for many applications.

Labor cost differences become apparent when comparing equipment efficiency. With a professional-grade machine, labor costs might run $0.30-0.45 per board foot, while the same installation using entry-level equipment could require $0.50-0.75 per board foot due to slower application rates and more frequent equipment adjustments.

The energy savings for clients represent a compelling selling point that helps justify premium pricing. Properly installed spray foam can reduce heating and cooling costs by 30-50% compared to traditional insulation, delivering lifetime savings that far exceed the initial cost difference.

Performance advantages of spray foam include superior air sealing, moisture control, and structural reinforcement that traditional insulation cannot match. These benefits allow contractors to command premium pricing while delivering genuine value that clients recognize through increased comfort and reduced energy bills.

When calculating overall project cost with different machine options, consider that higher-quality equipment typically allows for more competitive pricing through efficiency gains. A contractor using premium equipment might offer a complete installation package at $1.25-1.75 per board foot, compared to $1.50-2.00 for those using budget equipment yet still maintain better profit margins.

Hidden Costs of Ownership

Maintenance requirements represent significant hidden costs that vary dramatically between equipment classes. Budget machines typically require maintenance every 20,000-40,000 board feet of application, while premium systems might operate for 100,000+ board feet between service intervals. Annual maintenance costs typically range from $800-3,000 depending on machine complexity and usage patterns.

Replacement parts availability and pricing create another cost differential. High-end machines from established manufacturers offer standardized components with predictable supply chains, while imported or budget equipment might require difficult-to-source parts that extend costly downtime during repairs.

Training costs for operators vary based on machine complexity and manufacturer support. Professional systems typically include initial training but may require $500-1,500 for advanced operator certification. These educational investments pay dividends through improved application quality and reduced material waste.

Transportation and storage considerations add practical costs beyond the purchase price. Professional equipment might require dedicated vehicles or trailers ($5,000-10,000) and temperature-controlled storage environments. These logistical requirements should factor into the total investment calculation.

Insurance requirements increase proportionally with equipment value and project scale. Professional contractors typically need specialized coverage for equipment ($1,000-2,500 annually) plus general liability and completed operations insurance that can add $5,000-15,000 yearly depending on business volume and territory.

Financing and Leasing Options

Equipment financing programs designed specifically for contractors offer an accessible path to owning professional-grade spray foam machines. These programs typically require 10-20% down payment with financing terms of 36-60 months at interest rates between 5-12% depending on business credit profile and equipment type.

Lease-to-own arrangements present an attractive alternative with lower initial commitments and built-in upgrade paths. Monthly payments typically run 2-3% of equipment value, with options to purchase at predetermined residual values or upgrade to newer models at lease end.

The tax advantages of equipment investment deserve careful consideration, as Section 179 deductions may allow for immediate expense recognition up to $1,050,000 (2024 limit) rather than long-term depreciation. This benefit effectively reduces the real cost of premium equipment by 21-37% depending on tax bracket.

Manufacturer financing programs often provide the most favorable terms, with some offering promotional rates as low as 0-3.9% for qualified buyers. These programs typically include maintenance packages and extended warranty options bundled into the financing structure.

When comparing financing versus purchasing outright, ROI calculations must include the opportunity cost of capital allocation. Many contractors find that financing premium equipment makes financial sense even with available cash, as the productivity gains often exceed financing costs while preserving capital for materials and growth opportunities.

Where to Purchase: Market Availability and Suppliers

Alibaba and other online marketplaces offer access to a wide range of imported spray foam equipment, typically at 30-50% lower listed prices compared to domestic alternatives. However, these savings come with considerations regarding warranty support, parts availability, and quality consistency that merit careful evaluation.

US-based suppliers like Polymac USA, Master Pack, and PMC provide comprehensive equipment packages that include training, support, and warranty services. Their pricing typically ranges from $10,000-30,000 for professional systems, reflecting the added value of domestic support infrastructure.

Purchasing direct from manufacturer versus through distributors presents different cost structures. Manufacturer direct purchases sometimes offer 5-10% price advantages but may require larger minimum orders. Distributors typically provide local support, training resources, and bundled material programs that add value beyond the equipment itself.

Bundled packages with materials and accessories often represent the best overall value. These packages typically include starter chemical sets, multiple spray tips, personal protective equipment, and initial training at 10-15% less than purchasing components separately.

The used equipment marketplace offers potential savings of 40-60% compared to new machines, but requires careful evaluation of maintenance history, component wear, and remaining service life. Reputable equipment resellers typically recondition used machines and offer limited warranties ranging from 30-90 days.

Installation Requirements and Setup Costs

Facility modifications needed to accommodate spray foam equipment vary with machine size and type. Professional systems typically require dedicated electrical circuits (30-50 amp, 220V service) that may cost $500-1,500 to install if not already available. Proper ventilation systems add another $1,000-3,000 for compliant installations.

Power requirements represent a significant consideration, with professional machines consuming 40-60 amps at peak operation. This often necessitates electrical service upgrades for older facilities or mobile operations, adding $2,000-5,000 to the total setup investment.

Air compressor specifications must match machine requirements, with high-pressure systems needing compressors capable of delivering 15-25 CFM at 100+ PSI. These industrial-grade compressors typically cost $2,500-4,500 and require additional electrical capacity.

Chemical storage considerations include temperature-controlled spaces (55-85°F) with proper ventilation and spill containment measures. Meeting regulatory requirements for isocyanate and polyol storage typically adds $1,500-3,000 to facility preparation costs.

Safety equipment and ventilation requirements include supplied air respirators, chemical-resistant suits, and mechanical ventilation systems. This essential safety gear adds $2,000-5,000 to the initial investment but proves non-negotiable for professional operations concerned with worker health and regulatory compliance.

Machine Selection Based on Project Applications

Residential versus commercial applications drive different equipment requirements. Residential projects typically involve smaller areas and intermittent application, making mid-range machines ($5,000-15,000) suitable. Commercial projects demand higher output, greater reliability, and more precise control, justifying premium equipment ($15,000-30,000).

Agricultural and industrial use cases often involve large open areas with minimal obstructions, allowing for efficient application with high-output machines. The scale of these projects typically justifies professional equipment that can maintain consistent output through extended operation periods.

Roofing applications versus interior insulation present different demands on equipment. Roofing requires machines capable of extended hose runs (200+ feet) and consistent performance in variable weather conditions, often necessitating more powerful heating systems and pressure management capabilities.

Mobile applications versus fixed installation setups influence equipment selection significantly. Mobile contractors require compact, durable systems that withstand frequent transportation and operate reliably with variable power sources. Fixed installations can accommodate larger equipment with higher output but less portability.

Specialty applications like marine environments, cold storage facilities, or hazardous locations may require customized equipment features such as enhanced corrosion resistance, extreme temperature capabilities, or intrinsically safe electrical systems that add 15-30% to standard equipment costs.

Maintenance and Longevity Factors

Regular maintenance schedules significantly impact machine lifespan and performance reliability. Professional-grade systems typically require daily purging procedures and weekly seal inspections, with more comprehensive maintenance every 3-6 months depending on usage volume. Adhering to these schedules can extend equipment life by 30-50%.

Compatible chemicals directly affect equipment longevity, with premium formulations containing fewer abrasive fillers and better stabilizers that reduce wear on pumps, seals, and spray components. The slightly higher cost of quality chemicals ($0.05-0.10/board foot) pays dividends through reduced maintenance costs and extended equipment life.

Cleaning procedures represent critical maintenance activities that directly impact operational reliability. High-quality flush agents and thorough purging protocols prevent material curing within components, avoiding costly repairs that can reach $2,000-5,000 when improper cleaning leads to system contamination.

Component replacement schedules vary by machine type and quality. Entry-level machines typically require pump rebuilds every 50,000-100,000 board feet ($800-1,500), while professional systems might operate for 200,000-300,000 board feet between major service intervals.

Manufacturer support and spare parts availability dramatically affect downtime costs when issues arise. Premium manufacturers maintain extensive parts inventories and offer next-day shipping programs that minimize costly downtime, while budget equipment may require weeks for parts sourcing from international suppliers.

Environmental and Safety Considerations

Material safety requirements when handling polyurethane foam chemicals necessitate comprehensive protection for operators. Personal protective equipment including supplied-air respirators, chemical-resistant coveralls, and gloves represents an investment of $1,500-3,000 per operator but remains essential for health protection and regulatory compliance.

Environmental benefits of spray foam applications include significant energy efficiency improvements that reduce building carbon footprints. Professional-grade equipment delivers more consistent cell structure and better adhesion, maximizing these environmental benefits through superior installation quality.

Regulatory compliance requirements continue to evolve, with increasing focus on worker protection, chemical management, and emissions control. Meeting these standards requires ongoing investment in training, documentation systems, and equipment upgrades that add 5-10% to operational costs but protect against significant non-compliance penalties.

Certifications and training required for professional use include manufacturer-specific equipment operation courses, SPFA Professional Certification Program credentials, and OSHA compliance training. These educational investments typically cost $2,000-5,000 per operator but provide essential knowledge for safe, effective operations.

Insurance considerations for spray foam contractors include general liability coverage with completed operations protection, typically costing $5,000-15,000 annually depending on business volume. Equipment insurance adds another $1,000-3,000 annually but proves essential when protecting valuable assets against damage, theft, or loss.

User Experiences and Industry Insights

Contractor testimonials consistently highlight the relationship between equipment investment and business success. Those using professional-grade machines report 30-50% higher productivity and better customer satisfaction compared to budget equipment users, citing more consistent application quality and fewer callback issues.

Real-world performance feedback across machine types reveals that initial price often inversely correlates with ongoing operational challenges. Budget machines ($1,500-5,000) frequently experience pressure fluctuations, inconsistent heating, and higher maintenance requirements that impact installation quality and contractor profitability.

Unexpected benefits of higher-end machines include significantly reduced material waste through precise ratio control and better atomization. Contractors report 10-15% lower material consumption with premium equipment, representing thousands in savings annually for busy operations.

Common frustrations with budget equipment include frequent maintenance requirements, difficulty sourcing replacement parts, and inconsistent performance in challenging conditions. These limitations often lead contractors to upgrade prematurely, effectively increasing the true cost of ownership beyond initial savings.

Industry experts consistently recommend matching equipment investment to business volume, suggesting that full-time contractors apply at least 10,000 board feet weekly should invest in professional-grade systems ($15,000+) to maximize efficiency and quality while minimizing per-job costs.

Final Recommendations and Decision Framework

Matching machine investment to business stage and volume represents the most critical decision factor. Startups applying less than 5,000 board feet weekly might begin with mid-range equipment ($5,000-15,000), while established contractors should invest in professional systems ($15,000-30,000) that deliver lower per-job costs through efficiency and reliability.

Key features worth paying more for include hydraulic drive systems, digital ratio monitoring, and advanced heating controls. These components add $5,000-10,000 to machine cost but deliver tangible benefits through consistent application quality, reduced material waste, and lower maintenance requirements.

The appropriate time to upgrade from entry-level equipment typically arrives when job volume exceeds 7,500-10,000 board feet weekly or when project complexity demands greater precision. At this stage, the productivity improvements and material savings from professional equipment quickly offset the higher investment cost.

Cost-effective alternatives for specific applications include considering used premium equipment (40-60% of new cost) from reputable dealers or lease-return machines that offer professional capabilities with significant savings. These options can deliver 80-90% of new machine performance at substantially lower investment levels.

Building a complete spray foam business system extends beyond just the machine to include proper training, quality materials, comprehensive safety programs, and effective marketing. The most successful contractors view equipment as just one component in an integrated business approach that prioritizes installation quality and customer satisfaction.

Frequently Asked Questions

What's the minimum I should spend on a spray foam machine as a beginner?

For beginners planning to spray foam professionally, I recommend budgeting at least $5,000-8,000 for a reliable entry-level machine. While cheaper options exist, machines below this price point typically lack the consistency and durability needed for commercial work.

How much more productive are high-pressure systems compared to low-pressure ones?

High-pressure systems typically apply foam 3-4 times faster than low-pressure alternatives, with application rates of 40-50 pounds per minute versus 10-15 pounds for low-pressure systems. This productivity difference can dramatically impact job completion times and profitability.

Do I need different machines for closed-cell and open-cell foam applications?

A single professional-grade machine can typically handle both foam types with proper setup adjustments. The key requirement is having a system with adjustable pressure and temperature settings to accommodate the different processing requirements of each material type.

How long does a typical spray foam machine last?

With proper maintenance, professional-grade spray foam machines typically last 7-10 years, while budget equipment might need replacement after 2-4 years. The service lifespan directly correlates with initial quality, maintenance practices, and application volume.

Can I finance a spray foam machine with no money down?

Several equipment financing programs offer zero-down options for contractors with established credit histories and 2+ years in business. However, these arrangements typically include higher interest rates (8-12%) compared to traditional financing with 10-20% down payment.